BASIC DATA

| Model Number |

Full Input in

(BTUH) |

Flue Dia. |

| WH7-1005A |

999,000 |

6″ |

| WH7-1505A |

1,500,000 |

8″ |

| WH7-2005A |

1,999,000 |

8″ |

Features:

- 97% efficiency. Condensing, Cat IV venting required.

- Brass headers and pumps with copper finned-tube primary heat exchanger. Cupro-nickel tubes available as options. CSA Low Lead Certified 0.25% lead

- Minimum continuous inlet water temperature (50°F)

- Electronic modulating gas valve and burner, up to 7:1 turn down

- Small footprint, less than 11 square feet

- On-board diagnostic center, real English, no codes

- All models indoor/outdoor construction

- Complete cabinet protects all controls and wiring

- Certified under SCAQMD rule 1146.2. Meets all Low NOx regulations.

- Suitable for altitudes up to 10,000 ft. (derate above 5,000 ft.)

- Primary-secondary piping required.

- 0-10 VDC Remote set-point BMS Interface

- 0-10 VDC Direct Drive

- Available for natural gas or propane.

- VERSA IC® control package.

- Built-in cascade function for up to 4 heaters.

- Modbus® RTU port (RS485).

Options:

- BACNet IP, BACnet MS/TP, Modbus TCP, N2 Metasys (B-85)

- Lonworks (B-86)

- Centrotherm® Polypropylene Vent Adapter (D-33)

- Alarm with 4” Bell (E-5)

- Low Water Cutoff (F-10)

- Condensate Neutralizer (Z-12)

- PVC Vent (Factory-Installed ONLY) (D-32)

1. Low Voltage Wiring Terminal

Up front and easy to get to. Makes sensor wiring and BMS wiring simple and clean.

2. Versa IC Board

The Versa IC, Integrated Control system is CSA listed and certified as a combined temperature, safety, and ignition control device. Easy front access to all field wiring. This includes outdoor sensor, DHW sensor, system alarm, Modbus BMS port and 0-10V DC input connections.Each unit comes factory-equipped with cascade control capability. Simple, quick access daisychain of up to 4 boilers, link to Raypak Temp Tracker Mod+ Hybrid Master control for up to 16.

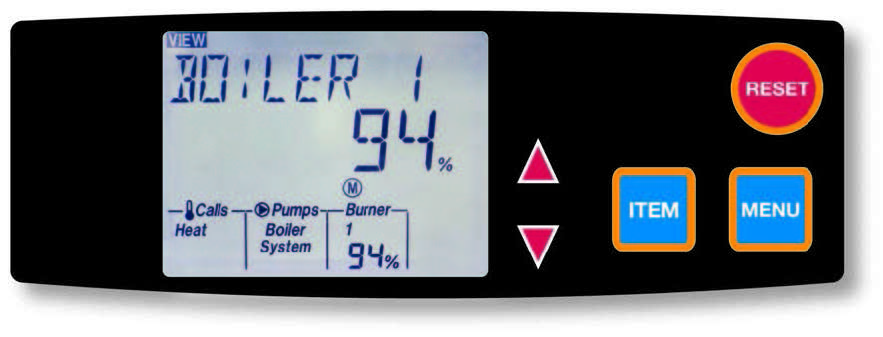

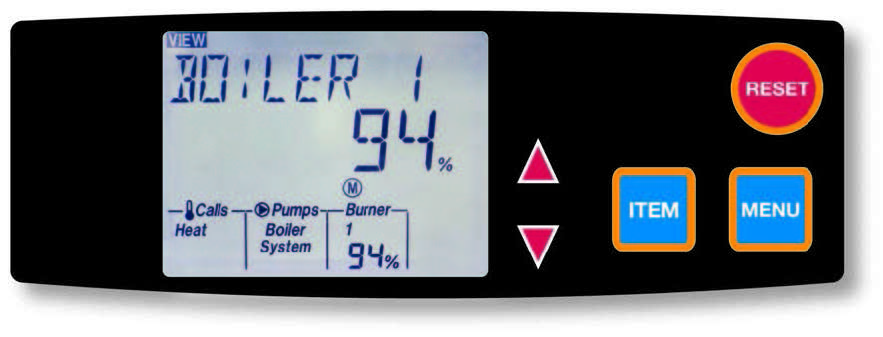

3. Control Interface

Large easy to read (3.5”) LCD display. Will continuously monitor flame strength (µa) sensor temps, BMS signal (0-10V) set points, delta-T, all safety signals, full diagnostics and fault history for last 15 events.Simple touch pad settings. Everything you need from set-up to service is at your fingertips, all in one location.

4. Combustion Air Blower

Cast-aluminum, non-sparking construction. The state of-the-art variable-speed blower is controlled by the on board Versa IC integrated controller and works in smooth harmony with the main gas valve.

5. Dungs Gas Valve

The XTherm uses a state-of-the-art main gas valve manufactured in Germany. This precision gas valve works in perfect unison with the combustion air blower.The result is silky smooth light-offs and a 7:1 turndown.

7. Vent Pressure Switch

Monitors vent pressure and provides safe shutdown if back pressure is excessive.

8. Gas Inlet

The XTherm will operate at 100% full rate with gas pressures as low as 4.0” w.c.

9. Water Outlet

With PRV and T & P gauge installed.

10. Boiler Pump

Sometimes referred to as the primary pump. This pump keeps flow through the heat exchanger

11. Water Inlet

The XTherm can accept 50°F continuous inlet water temperature and as low as 32°F during system startup.

12. Cold Water Protection

The XTherm comes factory equipped with a built-in Cold Water Protection system. This advanced water control system keeps the inlet water temperature to the non-condensing heat exchanger above 120°F, regardless of the incoming water temperature. It constantly self-adjusts and regulates the incoming water flow while still maintaining a constant delta-T in the heat exchanger.

13. Flue Outlet

The stainless steel flue outlet is compatible with CAT IV stainless steel. PVC or CPVC vent material may be used in conjunction with the D-32 vent option on the XTherm. Also available with option D-33 Polypropylene Vent material. Dramatically cut your installation costs by using these non-metallic vent materials.

14. 316L Stainless Steel Condensing Heat Exchanger

Recovers waste heat to boost efficiency into 96%+range. The XTherm utilizes a high-grade stainless steel heat exchanger. This allows the corrosive combustion condensate to be collected safely without damaging the heater. There is a condensate disposal connection on the rear of the heater. The XTherm is also equipped with a condensate switch that will sense a blocked condensate drain, which protects the heater.

15. Vertical Non-Condensing Heat Exchanger

Cylindrical, multi-pass heat exchanger captures all radiant energy, eliminating the need for heavy refractory.

16. Drain Valve

One of two drain valves located at the bottom of the non-condensing heat exchanger. A third drain valve is located on the condensing heat exchanger. This allows for complete winterizing and drainage of the heater.

17. Viewing Port

Allows for easy burner inspection.

18. Weather-Proof Jacket

Heavy gauge galvanized steel with a UV-resistant Polytuf powder coat finish is impervious to weather and corrosion.

Xtherm® Cold Water Protection System

The XTherm comes standard with a state-of-the-art Cold Water Protection System factory-mounted and plumbed. Raypak’s Cold Water Protection system provides constant protection against condensation in the primary heat exchanger. The system utilizes one or two variable-speed pumps, depending on model size and type, to inject just the right amount of water from the main system loop into the boiler to maintain the optimum inlet temperature. This allows the full capacity of the boiler to be utilized to meet the system load, while at the same time continuously maintaining the optimum inlet water temperature to prevent condensation in the primary heat exchanger. For models using the twin-pump design, each pump acts independently giving the boiler up to a 10:1 flow turndown. All of this keeps the condensate where it belongs, in the stainless steel secondary heat exchanger.

Versa IC Boiler Control and On-Board Diagnostic Center

The VERSA IC onboard control package merges safety, ignition and temperature control, outdoor reset and freeze protection, plus system monitoring, alarm and diagnostics,and BMS transmission all in one Integrated Control Platform. Easy front access to read, setup and troubleshoot on a 3.5” LCD screen. The entire package is CSA certified, and listed for each individual function.

Inlet and outlet sensors factory installed in boiler. Remote sensor for system included. BMS all point diagnostics transmission port. 0-10V DC set point input standard. Also can drive and monitor external motorized auxiliaries such as extractors and louvers. Additional connections for auxiliary functions such as indirect DHW, and dry contact remote alarm relay are provided.

|

Safety Faults

Condensate Drain

Manual High Limit

Auto High Limit

Vent Pressure

High Gas Pressure

Low Gas Pressure

Controller Alarm

Flow Switch

Blower Switch

Factory Option

External Interlock

Cold Water Protection

|

|

Ignition Control Faults

Low Air

Flame- No CFH

Ignition Lockout

Low Water Cut-off or Low HSI Current

Low 24 VAC

Internal Control Fault

|

Service Videos:

• XTherm® Basic Startup Video (EN)

• XTherm® Vídeo Arranque Básico (SP)