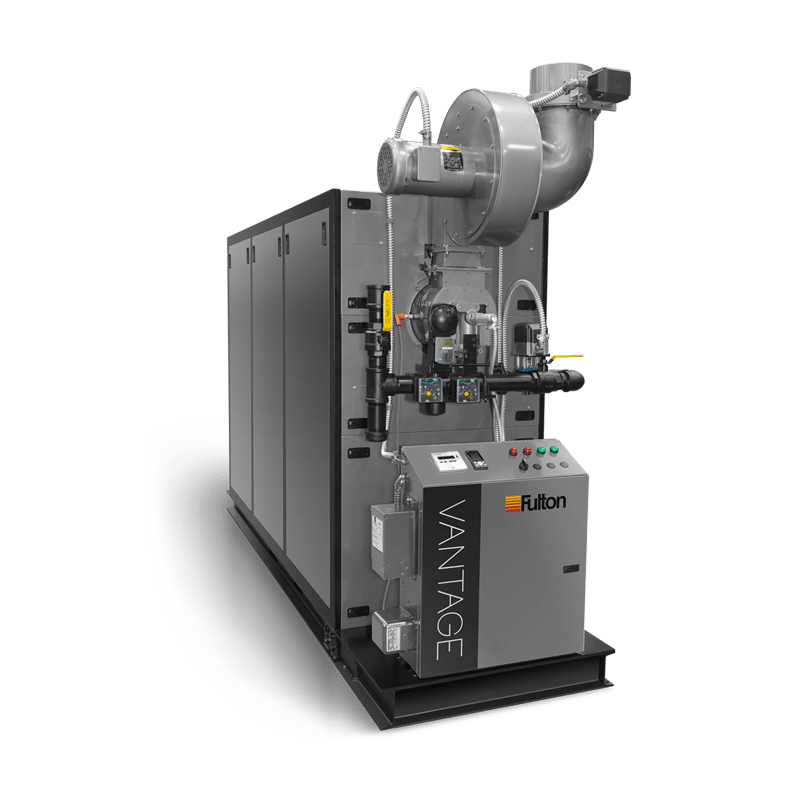

HEAVY-DUTY ENGINEERING

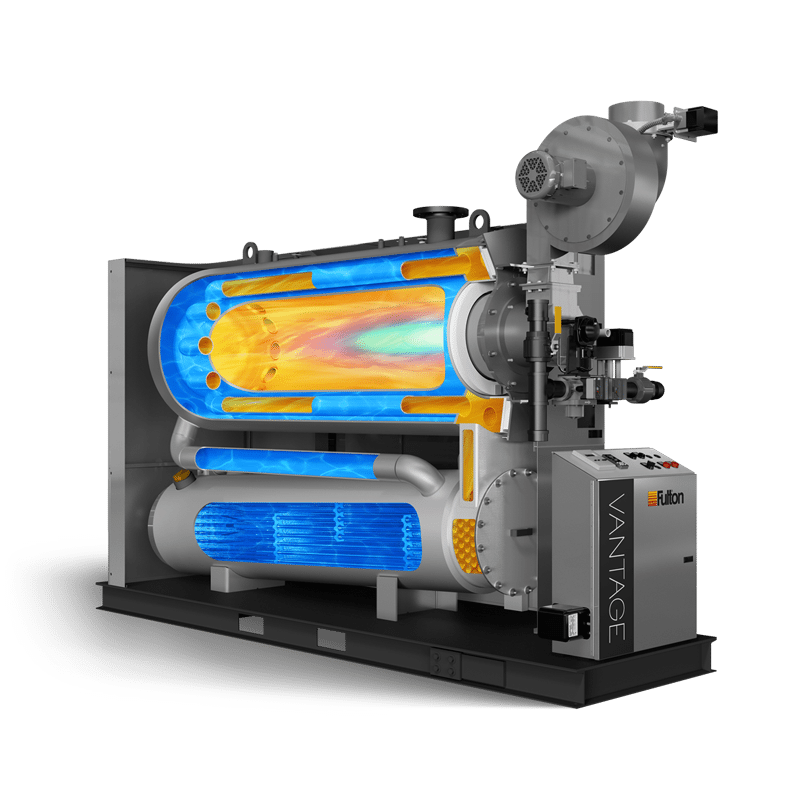

Fulton’s Vantage condensing boiler combines proven industrial-grade firetube construction with modern condensing boiler efficiency. Featuring a High-Mass and High-Volume pressure vessel, the Vantage provides exceptional tolerance for varying and sometimes unpredictable system conditions.

DURABLE & DEPENDABLE

- DESIGNED FOR VARIABLE PRIMARY FLOW

- This simplified piping method enhances temperature control, reduces design complexity, and maximizes efficiencies by delivering the lowest temperature water directly to the boiler with no blending.

- DUAL-FUEL OPERATION WITH #2 OIL

- For critical heating processes requiring redundancy in the event of a fuel disruption, Vantage boilers can be configured for dual-fuel operation.

- LIFETIME THERMAL SHOCK WARRANTY

MODULAR BOILER SEQUENCING

The optional touchscreen ModSync integrates multiple Vantage boilers into a cohesive system. This provides centralized intuitive monitoring of the entire boiler plant.

- BEST EFFICIENCY PERFORMANCE

- Highly optimized control matches boiler output to system load, thereby minimizing boiler cycling and extending equipment life.

- BUILDING INTEGRATION

- Modbus; BACnet configurable

- CUSTOMIZED PROGRAMS AVAILABLE

- Control sequences can be tailored to the unique needs of your application.

SIGNIFICANT ENERGY SAVINGS

- PRECISION COMBUSTION SYSTEM

- Vantage boilers feature linkageless air and gas servo motors

- CONSISTENT EFFICIENCY

- Reliable performance throughout varying environmental conditions and heating demands.

- LOW EMISSIONS CONFIGURABLE

OPTIMIZED ARCHITECTURE

- INDUSTRIAL DURABILITY: The fully wetted furnace chamber and large passageways keep stresses low and allow for full input without flame impingement on gas or #2 fuel oil.

- ADVANCED MATERIALS: The Duplex Alloy Stainless Steel heat exhanger features superior strength, lower stresses, and improved corrosion resistance over conventional 316L and 439 grades used by competitors.

- ROBUST PRESSURE VESSEL: Precision robotics and ASME-certified welders perform the impressive workmanship that goes into the Vantage pressure vessel. It’s engineered for unsurpassed durability in high demand commercial and industrial applications; a zero-flow condition will not harm the boiler.

DUAL-FUEL PEACE OF MIND

FUEL VARIETY AND FLEXIBILITY

Vantage boilers include packaged power burners that can be configured for a wide variety of fuels.

- NATURAL GAS and #2 FUEL OIL

- PROPANE and #2 FUEL OIL

- NATURAL GAS and PROPANE

- B-100 BIODIESEL OPTIONS AVAILABLE

SIMPLIFIED OPERATION

With automatic fuel switchover capabilities, changing fuels is as easy as flipping a switch.

- FULL BTU/HR INPUT ON BOTH FUELS

- DIRECT SPARK OIL IGNITION

- NO GAS PILOT REQUIRED ON OIL

- DOES NOT REQUIRE COMPRESSED AIR

FULL-TIME FUEL OIL BOILER

- ULTRA-HIGH EFFICIENCY

- Condensing operation on gas and <15 ppm sulfur #2 oil; non-condensing on standard #2 oil.

- FUEL CURTAILMENT APPLICATIONS

- Customers may qualify for lower natural gas rates with the ability to operate on a second fuel.